Pre-installation Guidelines

Better use 25mm pipeline instead of 20mm to ensure better pressure of water. Lay pipeline straight & vertical to get maximum water pressure.

Keep the number of bends in the pipeline to the maximum, to get good water pressure.

All pipelines should have Vent

Hole-to-Hole distance for mixers should be standard 165mm for trouble free installations of mixers.

Outlet of Storage Tank should be minimum 5cm above the bottom to avoid dust, sand and foreign particles flowing with water into the fittings.

Clean the overhead tank and pipelines properly before fixing the fitting/taps to avoid

Don't use excessive force to tighten the fittings. Excess length of the threads should be cut to suit the space inside the elbows: also wrenches and

Test all the concealed fittings for leakage before plastering and fixing of tiles.

Please get your Plumbing done by experienced plumbers only.

Post-installation Guidelines

Cover the taps / mixers with poly pack after installations, till they are put to regular use, to protect the finish from dust, strains, paint, chemicals and damages.

Clean the aerators (Foam Flow) at regular intervals to maintain good flow of water.

Fittings should be operated gently while turning off. Over-tightening gives friction to threads that reduce the files of the fitting.

Do not lean or put excessive weight on taps. Excessive weight can damage or even break the taps.

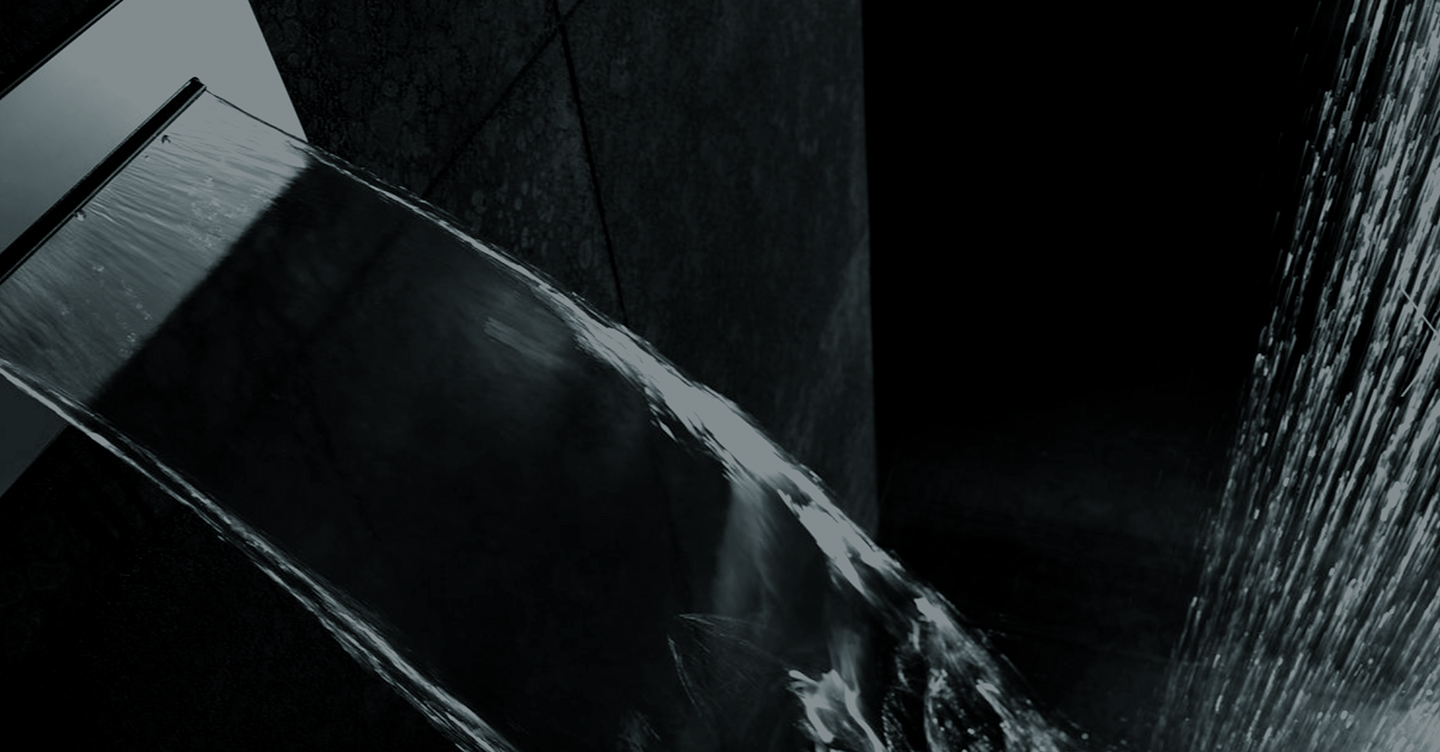

The following chart gives you an indication of the minimum required for getting a good performance from bath fittings.

| S.No | Product | Min |

Min |

Min |

|---|---|---|---|---|

| 1 | QT, H/T or F/T fittings with Single Spindle | 10 PSI | 0.7 Kgf | 07 meters |

| 2 | Q/T, H/T or F/T Mixers | 15 PSL | 1 Kgf | 10 meters |

| 3 | Single Lever Mixers | 20 PSI | 1.5 Kgf | 15 meters |

| 4 | Single Function Showers | 15 PSI | 1 Kgf | 10 meters |

| 5 | Multi Function Showers | 30 PSI | 2 Kgf | 20 meters |

| 6 | Flush Valves and Flush Cocks | 07 PSI | 0.7 Kgf | 207 meters |

? Kindly note that these figures are merely indicative. Water Flow rate depends on various other factors like Water Salinity, Dissolved constituents bends in pipelines, diameter of pipes used.

Half Turn ( New FRT Technology ) / Quarter Turn

PLATO internal fittings are made of Brass, which has high tensile strength & is corrosion resistant

PLATO internal fitting is made of Drop Forged Bonnet, the sturdiest form of casting, Valve & Spindle are made of extruded rod whose composition is lab tested

Advance international Double 'O' Ring protection is provided at the bottom of the spindle to stop water entering the threads; this keeps threads lubricated resulting in lesser wear & tear and longer life.

Grease used for Threads as well as 'O' rings are Silicon based Compound Food Grade Grease, which are specially made for Metal-to-Metal and Rubber-to-Metal contact as per requirement.

Ceramic Disk is also tested for Alumina and Silica content, we test that Alumina content

Single Lever Cartridge

Ceramic Disk is also tested for Alumina and Silica, we test that Alumina content

Warranty Terms

Dear Customer, thanks for choosing PLATO. Your PLATO product is warranted for 5 years against any manufacturing defect, however warranty is

Maximum liability of the company is limited only to repair or replacement of the piece.- Warranty is not accepted in case of improper or incorrect use or installation, normal wear & tear, careless use and improper maintenance etc.

- Plastic, Rubber and A.B.S parts are not warranted against breakages and natural wear & tear.

- No warranty for

mutilated & broken parts/pieces. Company is not liable for any other loss, damage or expense born by the customer.- In all cases

decision of the company will be final and binding. - All Disputes are subject to Delhi Jurisdiction only.